WhatsApp)

WhatsApp)

Carbon black is produced either by thermal decomposition or partial combustion method, which includes oil or natural gas as a feedstock. It is produced by four different processes, which are the furnace black process, channel process, and acetylene black process, and Lampblack process.

239000006229 carbon black Substances 0.000 title claims abstract description 74 It is a further object of this invention to provide a process for producing a carbon black having a tint residual of less than -5 in commercial quantities.

History of carbon black. Carbon black was called "soot" in the west and "shouen" in the east. In the 1740's, plant production started in the United States, and because of the production method used, it was then called "lampblack." The term "carbon black" originated in the 1870's, when products manufactured from natural gas were sold under this ...

The Carbon Black & Coker Project is anticipated to produce 40,600 tonnes of two different grades of Carbon black per year, and 430,000 tonnes of high value anode grade calcined coke. The firm's multi .

Jan 01, 2015· The process that produces hydrogen and carbon black from a hydrocarbon feedstock is called the Kværner process or the Kværner carbon black and hydrogen process. The name comes from the developer (Aker Kværner Solutions of Norway), which first used the process in the 1980s.

China is now the largest consumer of carbon black in the world, with 35% of global consumption in 2016 and with more than 100 plants producing carbon black. Most of China's carbon black output is for universal rubber materials and there is still a supply shortage for low-rolling-resistance carbon black, high-performance carbon black.

Such a process would form a recycling loop for the carbon black recovered from waste tires. The overall objective of the project is to develop a process for producing carbon black from tire pyrolysis oil. The Phase I objective was to demonstrate the feasibility of making carbon black .

Apr 17, 2020· After the results of the pilot plant, the Kvaerner Company decided to build a plant on a commercial scale in Montreal (Canada). The plant, denominated Karbomont Hydrogen Plasma Black Reactor Plant (HPBR Karbomont Plant), started operations in 1998 and was used in the production of carbon black for tires [5,6].However, it was closed in 2002 and subsequently demolished in 2003.

Jan 18, 1983· A process for producing a polyethylene composition having fine particle size carbon black dispersed therein which process comprises: (A) intensive mixing from 20% to 50% by weight of carbon black with from 80% to 50% by weight of a low density polyethylene to produce .

A process for producing carbon black in a reaction system comprising a first zone where a heating fuel material and an oxygen-containing gas are mixed, and a high temperature combustion gas stream is formed, a second zone where a hydrocarbon starting material is mixed to the high temperature combustion gas stream to form carbon black, and a third zone subsequent to and down-stream of the ...

Process for production of carbon black . Dec 3, 1999 - Cabot Corporation. Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black .

Dec 21, 2016· An Introduction to Carbon Black. The furnace black process is the most widely used method for producing carbon black. It involves blowing feedstock oil into a specially designed reactor with internal temperatures of 2700°–3500° F. When the feedstock enters the reactor, it partially combusts to produce carbon black and tailgas.

Aug 18, 2019· Carbon black production process descriptions. Furnace Black Process. The furnace black process produces carbon black from 'carbon black feedstock' (also referred to as 'carbon black oil') which is a heavy aromatic oil that may be derived either as a by-product of the petroleum refining process or the metallurgical (coal) coke production process.

Previously, recovering carbon black from the same type of product for which it was intended was not possible – at least, not in a continuous process with a closed recycling loop. Many developers and .

Process for producing carbon black Download PDF Info Publication number US4340577A. US4340577A US06/212,433 US21243380A US4340577A US 4340577 A US4340577 A US 4340577A US 21243380 A US21243380 A US 21243380A US 4340577 A US4340577 A US 4340577A Authority US United States Prior art keywords carbon black acetylene

The overall objective of the project is to develop a process for producing carbon black from tire pyrolysis oil. The Phase I objective, to demonstrate the feasibility of making carbon black of acceptable quality, was successfully accomplished, with American Society for Testing and Materials-grade carbon blacks produced.

Jun 28, 2017· Traditionally, most carbon black (about 95 percent) is created through burning crude oil, using the 'furnace' process, with an average input of 2.5 litres of oil to manufacture 1 kilogram of carbon black. Current production of carbon black uses ± 31.751.465.900 litres of oil and is highly polluting, emitting more than 35 million tons of CO2 ...

Nov 23, 2017· Global Carbon Black Market 2017-2025 - Profiles of 34 Carbon Black Producers Including Product, Production Capacities and Revenues PRESS RELEASE GlobeNewswire Nov. 23, .

Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of heavy petroleum products such as FCC tar, coal tar, or ethylene cracking tar. Carbon black is a form of paracrystalline carbon that has a high surface-area-to-volume ratio, albeit lower than that of activated carbon.

Classification of carbon black by manufacturing process. Carbon black is produced with the thermal decomposition method or the partial combustion method using hydrocarbons such as oil or natural gas as raw material.. The characteristics of carbon black vary depending on manufacturing process, and therefore carbon black is classified by manufacturing process.

The Lamp Black process is the oldest commercial Carbon Black production process. It consists of a cast-iron pan that holds the liquid feedstock. It is surmounted by a fire-proof flue hood that is lined with refractory bricks. The air gap between the pan and the hood, as well as the vacuum present in the system, help regulate the air supply and ...

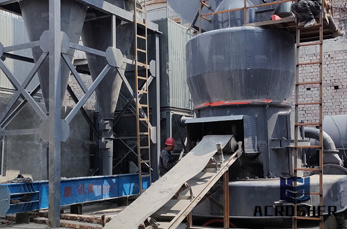

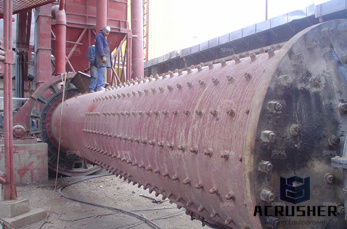

Beston carbon black processing plant is designed to deeply process the pyrolysis carbon black and common carbon black. It is great in process the pyrolysis carbon black, and it is also efficient in making minerals powder. Here are the main two applications of the plant. carbon black processing plant Different Usages of Beston Carbon Black ...

Jun 28, 2017· Traditionally, most carbon black (about 95 percent) is created through burning crude oil, using the 'furnace' process, with an average input of 2.5 litres of oil to manufacture 1 kilogram of carbon black. Current production of carbon black .

the United States to manufacture carbon black, the oil furnace process and the thermal process. The oil furnace process accounts for about 90 percent of production, and the thermal, about 10 percent. Two others, the lamp process for production of lamp black and the cracking of acetylene to produce acetylene black, are each used at 1 plant in ...

WhatsApp)

WhatsApp)