WhatsApp)

WhatsApp)

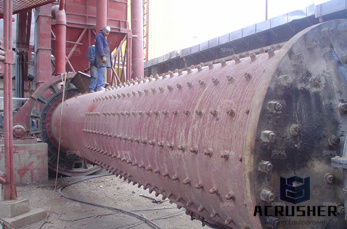

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool.Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (e.g., low surface roughness) and high ...

In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm (150-15000 RPM, it may change according to the types of grinding machine) with the help of v-belt and cone pulley the grinding wheel also starts rotating and we perform the operation.

CNC Grinding Machines Computer numerical control (CNC) is the machining evolution of numerical control (NC), which leverages precise programmed commands. This is in contrast to manual control, which uses wheels and levers to adjust equipment.

Find here Used Grinding Machine, Second Hand Grinding Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Used Grinding Machine, Second Hand Grinding Machine, Used Jig Grinding Machine across India.

How to Use a Surface Grinder Machine: A surface grinding machine is used to produce a smooth accurate finish on either metallic or nonmetallic materials. It uses a round rotating abrasive grinding wheel that remains stationary (but rotating) while the feed table (with work attached) is run in a reciprocating motion (left and right) under the ...

Let me start by saying that at $25 this grinder is a steal. The grinder comes without a case. It has a handle that could be used either left/right handed. The grinder also arrived with one grinding disk. Over all, the grinder is a steal for the prize.

use of styles grinding machine Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

Dec 01, 2016· Some builders classify their machines by the type of grinding zone. With moving-zone, or three-slide, machines, the grinding wheel is fixed during operation and the X-, Z- and B-axis (wheel inclination) movement is controlled from the regulating side. This arrangement provides a compact design and excellent rigidity.

5. Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser. 6. Turn the machine off after making contact with the dresser. 7. Turn the machine on again. While the wheel is spinning, lower the grinding wheel down in .

Each grinding machine shall be inspected regularly before use, and colour coded Abrasive wheels, grinding or cutting discs without the manufacturer's maximum RPM marked shall not be used. RPM (rotation per minute) of the wheel shall be more than a grinding machine if machine RPM exceeds than a wheel can break easily.

Machine tool - Machine tool - Basic machine tools: Hundreds of varieties of metal machine tools, ranging in size from small machines mounted on workbenches to huge production machines weighing several hundred tons, are used in modern industry. They retain the basic characteristics of their 19th- and early 20th-century ancestors and are still classed as one of the following: (1) turning ...

use of styles grinding machine - earthstonegranites. Grinding machine - Wikipedia. A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel . Get Price And Support Online;

Peel grinding machines offer a modern approach that achieves flexible grinding operations of a variety of diameters, grooves, thrust faces and forms using one set-up. Peel grinding is often compared with hard turning where a tool is traversed along a hardened workpiece following an appropriate form. Peel grinding operates in a similar mode removing a narrow strip of material as the grinding ...

The ID grinding quill is a shaft that's housed within the grinding machine's motor and supports and rotates the grinding abrasive wheels. Because there are many different grinding machines with different applications, as well as varying spindles and wheels, there are also different styles of ID, or Interior Dimension, grinding quills.

Find here online price details of companies selling Grinding Machines. Get info of suppliers, manufacturers, exporters, traders of Grinding Machines for buying in India.

Home - use of styles grinding machine. Grinding machine Wikipedia. A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.

Title: Grinder Use Safety Training 1 Grinder Use Safety Training 2 Introduction. Grinders are dangerous tools that can cause severe injuries or even death. Grinders should be chosen for the reason of performing the job in the safest manner first and saving time last. Use other tools when the associated inherent hazards are less severe.

This grinding machine can be made from a cordless cut-off grinder and < $155 in parts. The new invention is demonstrated to be able to cut custom screws with variable (i) channel depths, (ii) screw diameters, (iii) screw lengths, (iv) pitches, (v) abrasive disk thicknesses, (vi) handedness of the screws, (vii) and materials (three types of ...

Aug 17, 2020· The grinding machine is a kind of tool which is used for grinding work pieces. Basically, it makes use of an abrasive wheel in the form of a cutting tool. The rough surface of the abrasive wheel shreds away small pieces of the work piece as needed. The grinding machine isalso called as a grinder. The grinding machines are used to precisely ...

Grinding machine, tool that employs a rotating abrasive wheel to change the shape or dimensions of a hard, usually metallic, body. All of the many types of grinding machines use a grinding wheel made from one of the manufactured abrasives, silicon carbide or aluminum oxide. The wheel is

It's quite loud for such a little machine (10.4 inches tall) and will fill your house with the noise of grinding blades. Those blades are high quality, and despite many of the internal gears and components being made out of plastic, it's both durable and easy to clean.

The grinding machine is a type of tool that is utilized for grinding work pieces. It basically use an abrasive wheel as the cutting tool. The rough surface of the abrasive wheel shreds off small portions of the work piece as required. It is also known as a grinder.

The grinding machine is utilized in a tool shop for various purposes such as finishing, forming, sharpening, cutting, roughing, snagging, cleaning, polishing, buffing, etc. However, while operating a grinding device, it may cause serious injuries to the operator or any person nearby. Hence, it is essential to observe the following safety ...

Used grinding machines for sale in India. TOS, Landis, Toyoda, and Studer. Find surface, cylindrical, belt and centerless grinders on Machinio.

WhatsApp)

WhatsApp)