WhatsApp)

WhatsApp)

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity.The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter ...

carded slag from the smelter. Discard slag may contain 0.5–0.7% lead/zinc and is frequently used as fill or for sandblasting. Slags with higher lead/ zinc) content—say, 15% zinc—can be sent for metals recovery. Leaching processes produce resi-dues, while effluent treatment results in sludges that require appropriate disposal. The smelting

With Doe Run's new hydrometallurgical lead smelting process, a proprietary lead-bearing solution is exposed to an electric current, which electrowins the lead metal to cathode sheets.

slag mineral equipment in philippines acherishedbirth. slag mineral equipment in philippines offers 1532 copper slag for sale products. About 15% of these are abrasives, 9% are copper scrap, and 6% are other copper. A wide variety of. Get Price Lead Slag Wholesale, Lead Suppliers. slag mineral equipment in philippines offers 353 lead slag products.

Gravity separating lead from slag. Gravity separation is suitable for processing a large density difference between useful minerals and gangue minerals or other raw materials. It is one effective method to process coarse grain, medium grain and fine grain (roughly boundaries is .

lead laboratory tin tantalum niobium ore separation . Feb 19, 2017 · When using cross-belt high-intensity magnetic separation equipment it was found Figure 1 shows the cumulative amounts of tantalum, niobium, and tin recovered in and many lead deposits in their lower horizons carry zinc and .

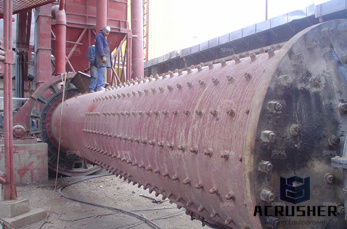

Smelting Lead-zinc Slag Gravity Separation Process Lead and zinc symbiosis in nature, particularly in primary deposit is intimate. They have common source of ore-forming materials and very similar geochemical behavior, have similar outer electron...

Henan Machinery & Equipment Company Limited. ... gold, molybdenum, lead and zinc, etc., for re-election,magnetic separation, flotation, cyanide, and other mineral extraction electrowinning technology we have a wealth experience. ... Artificial Sand and Aggregate Artificial Sand/Aggregates Steel Slag Comprehensive Recycle Construction Waste ...

Dross is distinguished from slag, which is a (viscous) liquid floating on the alloy, by being solid. Lead Dross shall consist of slag, dross, skimming or spilling from Lead melting operations. A scum formed on the surface of molten metal. Dross refers to the Lead oxides, copper, antimony, and other elements that float to the top of the molten Lead.

Metalcess provides Waelz Kiln for the recovery of zinc oxide from low grade zinc-bearing material including zinc leaching residue, zinc slag from lead smelting, zinc electrolyte purification precipitate, zinc dross from coating production, blast furnace flue dust,

lead zinc ore processing plant suppliers; zinc concentrate crusher in bulgaria; zinc ore beneficiation equipment; election lead zinc slag equipment; silver ore associated with zinc deposit; equipments used in production of zinc oxide; diameter of zinc ore after crushing and milling; how much does the zinc ore crusher cost; zinc ore process ...

Sep 10, 2013· Chemical analysis of the ISF slag is presented in Table 1.It is typical of an ISF slag with about 9.2% zinc oxide. Silica and alumina, which take part in the geopolymerization process, are significantly less than that found in fly ash, which has been used for making geopolymers in many previous studies (Kumar and Kumar, 2011, Kumar et al., 2007, Puertas and Fernadez-Jimenez, 2003, .

12.6 Primary Lead Smelting 12.6.1 General15 Lead is found naturally as a sulfide ore containing small amounts of copper, iron, zinc, precious metals, and other trace elements. The lead in this ore, typically after being concentrated at or near the mine (see Section 12.18), is processed into metallurgical lead at 4 facilities in the U. S.

Magnetic separation lead and zinc slag material technology Eliminate the pollution of lead smelting process to remove the slag and one of the valuable components get More; election lead-zinc slag equipment - greenrevolutionorgin election lead-zinc slag equipment;, slag through a variety of magnetic separators election the, Sulfuric Acid .

Lead and zinc are often related as coproducts in both source and metallurgical treatments, and the various combinations of slags, which include lead, lead-zinc, and zinc, are similarly produced. Figure 1 presents a general schematic depicting the slag production process for copper, nickel, and lead-zinc .

The lead slag stream, containing most of the 'fluxing' elements added to the sintering machine (predominantly silica, limestone, iron and zinc) can either be discarded or further processed to recover the contained zinc. The crude lead bullion, containing significant quantities of copper will then undergo 'copper drossing'.

Initial characterization of the lead blast furnace slag received from Herculaneum was through a) wet chemical analysis b) scanning electron microscopy and c) particle size analysis. The chemical analysis was performed by dissolution of the slag in aqua regia followed by elemental assay by atomic absorption for lead, zinc and iron. Lead and Zinc ...

lead and zinc concentrate usually have lower respective metal concentrations. During sintering, a blast of hot air or oxygen is used to oxidize the sulfur present in the feed to sulfur dioxide (SO2). An increasing proportion of the supply of both metals (over 50% for lead and 30% for zinc) is being met by recycling.

Zinc Slag Processing Machine Crusher For Sale ... Copper slag processing equipment in australia copper slag processing equipment in australiaCopper Slag General Information Process Products Patent Copper slag is an abrasive blasting grit made of granu cost of copper slag processing machine in australia for sale Slag processing plant cost in ...

Jan 06, 2014· is a professional manufacturer of mineral processing equipment, production of mineral production line equipment: molybdenum ore dressing equipment, lead-zinc ore processing equipment ...

Alibaba offers 330 lead slag products. About 9% of these are lead, 9% are other metals & metal products, and 2% are lead scrap. A wide variety of lead slag options are available to you, such as lead ingots scrap, lead sheet, and lead bar.

MOLTEN METAL SKIMMERS. Home > Products > MOLTEN METAL SKIMMERS. DY-KAST SUPPLY, your one stop shop for die casting and foundry supplies. We offer all types of Molten Metal Skimmers including, deep dish skimmers, heavy duty skimmers, square skimmers, and other miscellaneous size and shape skimmers for use in molten aluminum and all non-ferrous metals.

A wide variety of zinc slag options are available to you, There are 176 zinc slag suppliers, mainly located in Asia. The top supplying countries or regions are China, India, and Taiwan, China, which supply 73%, 18%, and 2% of zinc slag respectively. Zinc slag products are most popular in Mid East, Africa, and Southeast Asia.

May 29, 2017· The heavy legacy of lead in the world's most toxic town – in pictures Atop Black Mountain: More than 6m metric tonnes of lead slag form Black Mountain, a 30-meter pile of toxic lead .

WhatsApp)

WhatsApp)