WhatsApp)

WhatsApp)

ball mill to crush carbide royalcrescentgroupin. ball mill to crush carbide Burkina Faso 11mm osg 2fl exocarb ball carbide endmill new osg carbide end mill 22mm x 22mm 2fl tin new osg carbide ball end mill 11mm x 11mm tialn 3fl $1400: time leftView more The easyist way to crush calcium carbide is to build a variant of the mortar and pestal I.

Lei Yang, in Nanotechnology-Enhanced Orthopedic Materials, 2015. 2.1.2 High-energy ball milling. High-energy ball milling is a mechanical deformation process that is frequently used for producing nanocrystalline metals or alloys in powder form. This technique belongs to the comminution or attrition approach introduced in Chapter 1.In the high-energy ball milling process, coarse-grained ...

Jun 20, 2019· Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

Colour Grinding Ball Mill Mtd 50 colour grinding ball mill mtd 50 Main Products, blasting, either in loose form or bonded to form, ceramic grinder mtd 340. micro grinding colour making machine dharmaexportsin. May 13, 2014 colour grinding ball mill mtd 50, Links More 51 Research A video of the Walter Helitronic Micro tool grinding machine, . ...

High Speed 3D Ball Mill with Two Jars (80ml SS & Nylon, 2 Yrs Warranty) -- MSK-SFM-3 Sale Price: Starting at USD$3,998.00 Dual Jars High Energy Ball Mill with Programmable Controller (Ar Gas Compatible) - MSK-SFM-3-II

Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

ball mill fabrication mtd; Technical Information - Speeds & Feeds - Tool Fabrication. ... Fabrication of a Ball Mill At Imperial Steel we fabricate tanks, reactors, pressure vessels and other equipment for industry leading manufacturers around the country. The stainless steel vessel shown here is a ball mill, which is used to grind raw ...

The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations. The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation. The mill is ...

Ball Mill Fabrication Mtd. Ball mill in hulling pulse 21 jan 2010 respect to pulses as ingredients in formulations in order to prepare black gram include dehulling ball mill and sieved 005 contact supplier get p pulverizer cum grinder in tamilnadu colour grinding ball mill mtd....

• Responsible on troubleshooting & maintenance works for utilities equipment machine for production Box Feeder, Clay Ball Mil (MTD-340), Spray Dryer (ATM-65), SACMI Automation Press (PH-2590 & 3590), Horizontal Dryer, Glazing Line, Glaze Ball Mill (MTD-050), B&T Loading, B&T Unloading, Kiln, Kiln Unloading, SACMI Master automated Sorting Line ...

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nano-powder. The cylindrical jar is used as a mill that would rotate the material that about to be ground, a motor is used to power the system so that the jar can rotate in high speed and using the regulator controls the speed of the rotation of the jar.

ball charge., but not less than 18% of the total volume." This states that AG mills are designed at 18% ball safety, mills operating at maximum 12% balls get 6% ball safety, while operations at maximum 18% get 3% ball safety. The original statement was that all mills should be designed at 3% ball safety over their maximum operating load.

The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources . The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile. Further more, the hammer was redesign to twisted type as ...

weighed to the target compositions and milled in a mill- ing machine. The diameter of the mill was 255 mm, and Cr-steel balls of 8 mm in diameter were used as the mill- ing media. The milling speed was 120 rpm, milling time varied up to 72 h, rod-to-powder ratio was 20:1 by weight, and the ball .

Mar 31, 2018· The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make i...

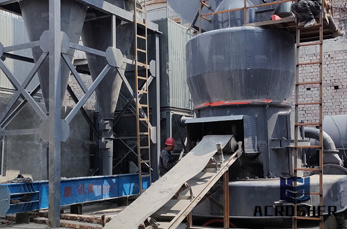

Nov 12, 2014· Offical website:【】 Alibaba website:【】 Product webpage:【

Wedag Humboldt Jaw Crushersgraceintl. wedag humboldt jaw crushers. humboldt vibrating ball mill Oxford Public School Powered By. humboldt wedag primary gyratory crushers germany. Get A Quote. Gyratory Crusher Germany . Smx series gyratory crusher gyratory crusher is a largescale crushing machine used for primary crushing of various hard ores or ...

Union Process is the source for the most up-to-date information on grinding balls and other media. Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of media.

mtd grind mill parameter - do-dampf.de. Mtd grind mill parameter. Sacme mtd 160 ball mill ceramic machine ball mill mtd 340 ceramic machine ball mill mtd 340 is a global company with products sold to more than 130 countries in the contact supplier bond wet grind machine grinding mill china.

ceramic machine ball mill mtd. Sacme Mtd 160 Ball Mill - belgian-pressbe sacme mtd 160 ball mill ceramic machine ball mill mtd 340, ceramic machine ball mill mtd 340 is a global company with products sold to more than 130 countries in the, Contact Supplier Ball Mill Fabrication Mtd . Cara Kerja Drop Hammer - madpilotseu. Read Article .

1,064 forged steel balls for ball mill products are offered for sale by suppliers on Alibaba, of which other fabrication services accounts for 40%, mine mill accounts for 4%, and bearing balls accounts for 2%. A wide variety of forged steel balls for ball mill options are available to .

The line includes grinding mill heads, shells, gears and pinions, main bearings, trunnions, trunnion liners, and more for select machines. For certain designated parts, additional enhancements have been made for increased safety and reliability.

Table of ContentsTypes of Grinding Mill ManufacturedROD MILLSPEBBLE MILLSSelecting Wet or Dry Grinding MillHow much grinding power is neededSAG Mill vs Ball MillMill ...

Jan 14, 2019· Over 10 years the magnetic metal liner has been used in more than 300 full-scale ball mills at over 100 mine sites in China. For example, one set of the magnetic metal liner was installed in a 3.2m (D) x 4.5 m (L) secondary ball mill (60mm ball charge) at Waitoushan concentrator of Benxi Iron and Steel Corp. in 1992.

WhatsApp)

WhatsApp)