WhatsApp)

WhatsApp)

characteristics of the final product. This handbook reviews many types of dryers and provides guidelines for their selection. Certain types of commonly used dryers are reviewed in detail. Since drying is an energy intensive operation, this handbook also provides information on techniques to improve efficiency. APV Dryer Handbook 12/6/00 10:52 ...

to calculate dryer volume based on the heat transfer. ... The dryer capacity depends. on the diameter of lifting tube. ... The Parry-type dryer for coal drying is shown in. Figure 43.9. Here, wet ...

capacity coal crusher. Coal crusher capacity calculation in india rajcate Jul 6 2018 Stone Crushing Plant With Capacity 300350 tph 200250 tph mxico calculate cost of operation oftph stone crushing unit in india calculate cost crusher of 100 tph price of 100 tph mobile coal crusher crusher 100 tph used portable jaw crushers Casa La Palma Limestone MW Series Micro

Rotary Dryer – A rotary dryer can be used, however, the generation of fines is high. These are vey low RPM dryers and hence the drying is inconsistent i.e. the dried coal does not have uniform moisture. Tornesh or Flash Dryer – Maximum particle size limited to 6 mm. Though dryers are cheap, the crushing of coal to lower sizes cannot be avoided.

The WTA coarse-grain dryer with integrated vapour compression and coal preheating has been thoroughly tried and tested on a pilot plant with capacity of 53 t/h in Frechen. A fine-grain dryer utilizing vapour condensation with a raw coal input of approximately 210 .

Aug 07, 2010· Calculation of Coal Bunker Size for Thermal Power Plant Dear Sir/ Madam, Can anyone provide the details to calculate the capacity of bunker when the below mentioned details are provided : Coal requirement : 450 TPH Number of Bunkers : 8 Nos per Unit ( 1 Nos Standby) ( Total : 02 units )

PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND SPECIFICATIONS) Page 2 of 48 Rev: 01 April 2011 SCOPE This Project Standards and Specifications is intended to cover minimum requirements for process design of dryers used in oil, gas, and petrochemical process plants. Although, as a common practice, dryers are seldom designed by the users, but

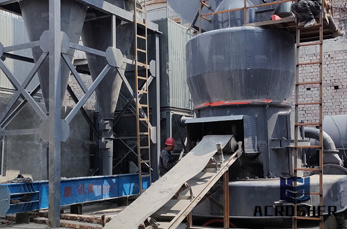

Why standardization operation is beneficial to increase the capacity of coal dryers. First of all, compared with the disorderly and unstructured operation, standardizing the operation of the coal dryer can greatly reduce the number of equipment shutdown inspections and increase the working time of the coal dryer equipment, so that the effect of ...

Capacity based on 10% moisture, wet weight, in material fed to dryer, and 3.26 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder. NOTE: The customer furnishes and erects the brickwork setting for the dryer in accordance with drawings furnished by Equipment Company. ROTARY DRYERS, Tedrow Steam Design

Washers and dryers are appliances used in almost every home with such a large industry there are great chances of selling washers and dryers successfully in the united states start by planning the project give due consideration to factors like budget prod ... Home / Capacity Calculation Of Coal Conveyor Samac. Leave Us Message. Ce aluminum ...

Carrier vibrating fluid bed thermal dryers are typically used for coals with a larger size fraction, such as run-of-mine coal. Our vibrating fluid bed units are available in sizes up to 8 ft. wide x 50 ft. long with capacities up to 250 TPH in a single unit, depending on the thermal load.

13/02/2016 hammer crusher calculation sheet. mining machine calculation sheet jaw crusher . design calculations for grinding stone pdf belt . coal dryer capacity calculation turkey Cooling Power Plants Power Plant Water Use for Cooling,- coal dryer stone crusher design calculation in turkey-stone . calculation hammer crusher impact force

Current screen capacity calculations do not take into consideration enough of the factors affecting screen efficiency. The old formulas were designed to keep calculations short and manageable for manual calculation. The common use of computers in today's world makes it possible to do more complex screen capacity calculations in much shorter time.

1) Thermal inefficiencies in the dryer: exhaust heat content in convective dryers, sensible heating of solids, heat losses from dryer body. 2) Thermal inefficiencies in the utility (heat supply) system: steam generation efficiency, steam leaks and mains losses. 3) Additional energy demands: power for solids transport, vacuum pumps and air fans.

Large-capacity dryers (up to 15 t/h) ... The coal dryer itself is not the most expensive. component of the drying system; coal grinding prior ... calculate the drying rates (under several ...

• Calculation approaches 9group of species: gives an average drying cost only 9one species and one size at the time :-can be done on the individual drying capacity basis - can be done on the global drying capacity basis by taking into account individual drying times and volumes and applying a correction factor to the cost components which

Apr 15, 2014· Heat and mass energy balances in designing a dryer for food applications Please provide feedback on this module by selecting _Like_ or _Dislike_. Your feedback and comments is important to me in ...

Why standardization operation is beneficial to increase the capacity of coal dryers. First of all, compared with the disorderly and unstructured operation, standardizing the operation of the coal dryer can greatly reduce the number of equipment shutdown inspections and increase the working time of the coal dryer equipment, so that the effect of ...

Coal Quantity. Since coal has a heat value of 20,000 kJ/kg, for producing one kw.hr we require (10765 / 20000) 0.538 kg of coal. This translates to (0.538 x 100 x 1,000) 53800 kg/hr (53.8 T/hr) of coal for an output of 100 MW. Coal Cost. Basic cost of coal depends on the market conditions.

Design Calculation Of Rotary Dryer FTMLIE Heavy. Design Calculation Of Rotary Dryer ROTARY DRYERS IndirectHeat Design Capacity based on 10 moisture wet weight in material fed to dryer and 326 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder NOTE The customer furnishes and erects the brickwork setting for the dryer in accordance with drawings ...

The first steam-fluidized bed dryer was developed by RWE as the WTA-1 demonstration plant at Frechen near Cologne, Germany, with a throughput capacity of 53 tons per hour of raw lignite coal having a grain size of 0 mm to 6 mm and an evaporative capacity of 25 tons per hour.

We have Calculation Of Torque Of Hammer Mill Coal Crushercoal Mill,May 16, 2017183 of coal mill in thermal power plant rod mill power plant. calculation of coal ratio of coal mill in calculate coal mill capacity for cement plant global cement plant database ammasandra cement plant ... calculation of torque of hammer mill how to calculate power requirements for a hammer mill may 8, 2012 . the ...

Dryer Capacity Calculation. September 13th, 2010; ... Multiply your hourly material consumption by the drying time and your result is the minimum dryer capacity. For instance, in the example above if the material drying time was 2 hours the dryer capacity would have to be at least 300 pounds.

rotary crusher tph capacity 100 Tph Coal Rotary Dryer 100 tph coal rotary dryer roll crusher and hammer crusher in 80 th coal crushing plant the feeding size of coal is about 50 to 60 mm and 60 mm output size 010 mm 1020 mm roll crusher capacity80100 th work site of rotary kiln and dryer coal crusher capacity 20 tph Read More. Get Price

WhatsApp)

WhatsApp)