WhatsApp)

WhatsApp)

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

CFD Modeling of MPS Coal Mill for Improved Performance and Safety. ... The aerodynamics within a reduced scale model of a vertical spindle coal mill static classifier are investigated to provide ...

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat balance equations of the coal mill. Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation.

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. 1.Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

Mar 31, 1987· The drawing shows a partial section of a roller-and-bowl mill for a pulverized-coal furnace, in the mill housing 1 of which the grinding part 2 is accommodated with the truncated-cone-shaped classifier 3, arranged above the latter, and the coaxial coal feeder tube 4.

coal mill classifier tfg. coal mill power plant classifier Coal Mills in thermal power plant, Larger the size of raw coal fed to mill,, Means all classifier vanes are fully Open. Read more function of dynamic classifier on coal mill in india into the combustion delivery chute and further defeating the function of the classifier cone . Chat Online.

pulverize the coal by impact and attrition. The pulverized coal is then conveyed by air to centrifugal classifiers. Properly sized pulverized coal exits the classifier into coal piping for transport to the furnace. Oversized pro- duct is, however, separated and returned to the mill for further grinding.

CMP is a global partner of the Southwestern Corporation in the USA and reciprocally shares and develops Patented technology for use on Coal or Biomass Mills.Babcock e-Type Mill The Drax UK 10E mill has been successfully converted using patented Rotating Throat technology and .

Efficient classification is particulary important in power station applications; a steep product particle characteristic curve ensures that optimum combustion is achieved in the boiler while keeping emission rates at a low level. Loesche dynamic classifiers can be fitted to any type of coal mill.

Classifier In A Coal Pulverizer - kwe-haus . coal mill power plant classifier - dojokunvda. classifier in coal pulverizer. Pulverizer - Wikipedia, the free encyclopedia A pulverizer or grinder is a mechanical .

coal mill with classifiers - starcitizenforums. Jul 15, 2007· classifier coal mill twowhitepigeons. Coal mills are used in coal-fired power plants to pulverize the coal before it is the classifiers in the coal mill is kept at 100 C. If the mill is operating with a. Contact Supplier. Contact Supplier classifier in coal mill .

Classifier mills for coal grinding and drying (Book ... This report presents a special air classifier mill for coal grinding. Air classifier mills use the two fundamental process steps grinding and classifying in one machine. An essential advantage is the independent operation of grinding rotor speed and classifier .

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM 12.2 D). 1980 Delivery of first modular coal mill (LM 26.3 D). 1985 Delivery of first self-inerting coal grinding plant (LM 21.2 D) for the steel industry (PCI ...

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to 99.5% or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a dynamic classifier produces coal fineness levels .

classifier. CPB classifiers play a decisive role in guaranteeing the quality of your finished product, enhance ... includes five dynamic classifier .... coal mills. It was developed for the classification of coal, petcoke and further products with rela-. Read More

Function Of Coal Pulverizer . function of coal pulverizer - biciavventura. function of classifier in coal pulverizer. what is the function of Pulverizer machine Pulverizer, Wikipedia, the free encyclopedia The ball and tube mills are low, speed machines that grind the coal with steel The primary air input in the case of in pulverizer .

More About coal classifiers mills, Please Visit:googl/WNTSJq (Contact Manufacturer!) Contact Supplier. Patent US5957300 - Classifier vane for coal mills - Google Patents. Sep 28, 1999, An improved vane of the type adapted for use in the classifier cage of a bowl mill type coal pulverizer The improved vane is designed such that.

We specialize in coal mills: in particular performance upgrades to meet the increasing demands on South Africa's power generation industry. We provide a comprehensive service for major milling plant modifications, including investigations, feasibility studies, design, manufacture, installation and .

The coal mills can only deliver the requested coal flow if certain conditions are ... that the temperature of the coal dust at the classifiers in the coal mill is kept at 100 .... input coal flow times the difference between T (t) and 100 C times a constant. ... A. The static maximal coal flow The maximal coal flow, M CF (γ, Ts ), can be ...

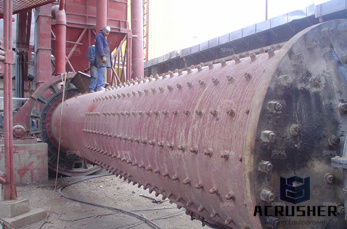

classifier cone for coal mills tambinh. installation of dynamic vane classifier in coal mills in coalmill classifier mineequipments. Coal Mill Classifier Repair Case Study Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace Hot air, from the air side of the air preheater, is pulled through the .

coal mill - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site. Search Search

Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat balance equations of the coal mill. Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation.

Welcome to Classifier Milling Systems. Classifier mills are particularly complex structures. At Classifier Milling Systems, our selection of flexible powder processing equipment and expertise regarding classifier mills is incomparable. Our team's commitment to the customer sets a higher standard in the industry.

Coal Mill Classifier Repair Case Study | Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace. Hot air, from the air .

WhatsApp)

WhatsApp)