WhatsApp)

WhatsApp)

Wet granulation can make the structure of organic fertilizer pellets more compact. However, the disadvantages of wet granulation is complex process. Because of special nature, organic fertilizer adopts wet granulation. Because the standard water content of organic fertilizer pellets is 10%. You should dry the organic fertilizer pellets after ...

Fiber cement siding is generally unaffected by both heat and flame. It has a Class 1(A) rating for fire/flame spread, the highest available rating. Disadvantages of Fiber Cement Siding Before and After Shots with New Fiber Cement Siding Photo Credit: wplynn Insulation Value

Shotcrete or gunning is the process of depositing mortar or granular concrete on the surface by preparing it with pressure applied by spraying.. Shotcrete is more economical than conventional concrete because it requires less formwork.. It only requires a .

advantages and disadvantages of wet method of cement. Discuss the differences advantages and disadvantages of the wet and dry processes of cement production In wet process raw material is quarried crushed and stockpiled separately In this method blending can be done during the fine grinding or after individual grinding Chat Here

Sep 25, 2018· In dry process all the materials in powder form are ground separated in the absence of water and then mixed in the desired proportion and the resultant product is fed into kiln for burning. This process results less consumption of energy. And low ...

The wet-process procedure generally produces less rebound, waste (when material falls to the floor), and dust compared to the dry-mix process. The greatest advantage of the wet-mix process is all the ingredients are mixed with the water and additives required, and also larger volumes can be placed in less time than the dry process concrete .

Mar 28, 2018· Wet process Mixing of Raw materials in wash mill with 35 to 50% water. Materials exiting the mill are called "slurry" and have flow-ability characteristics. Size of the kiln needed for manufacturing of cement is bigger. Raw material can be mixed easily, so a better homogeneous material can be obtained Fuel consumption is high i.e.,.

Advantage And Disadvantage Of Cement Manufacturing . Wet Process for Manufacturing of Cement The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process Learn More Advantages Disadvantages of Lean Production Bizfluent

Sep 22, 2018· Dry mix process and wet mix process are the two methods of shotcrete construction which are based on the time at which the water is added to the mortar or Shotcrete is a type of concrete or mortar mix that is shot onto a surface at high-speed. The shotcrete process can be performed in two ways, either using a dry mix or by means of a wet mix.

There are two types of process for manufacturing of cement: Wet manufacturing process: i) In this method, mixing and grinding of raw materials is done in a wet state. ii) All raw materials are transported to a ball mill or tube mill and ground to a consistent consistency of the solution with the addition of water.

The main advantage of cement tile is its durability. Cement is a very strong material, therefore you can be sure that your encaustic cement tile will not be easily scratched or destroyed. One other advantage is the patterns on it. Cement tiles are not painted like porcelain or other materials. The patterns are deeply buried inside the tile.

The Advantages of Wet Process Use in Cement Industry | . Grinding raw materials to create cement can be achieved by either using moisture, as in wet processing, or utilizing gas, as .

Sep 12, 2017· Advantages of concrete,Disadvantages of concrete,advantages and disadvantages of concrete,inert material acts as a filler and the binding materials. Rcc Concrete is considered as a chemically combined mass where the inert material acts as a filler and the binding materials act as a .

Jun 09, 2019· Regarding the advantages and disadvantages of cement, I think the answer from Zhengzhou Jianxin can help you. Advantages of ordinary cement: 1The cement has good plasticity before coagulation, and can be poured into various shapes and sizes of com...

Nov 15, 2017· The wet method is more appropriate in soft clays, silts and fine-grained sands with lower water content and in stratified ground conditions including interbedded soft and stiff or dense soil layers. The dry method is more suitable for soft soils with very high moisture content, and hence appropriate for mixing with dry binders.

Advantages and disadvantages of wet milling india crusher mill. . disadvantage of excess grinding of cement. disadvantages of dry grinding - karoux. disadvantage of excess grinding of cement. advantages and disadvantages of dry grinding, of wet process use in cement industry; x. advantage disadvantage cement - wildcer

Cement Manufacturing Process Know More. Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 ...

Cement Manufacturing Process Know More. Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and .

Burning : In this operation, the slurry is directly fed into a long inclined steel cylinder called Rotary kiln.Inthis kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones : In the wet process, the drying zone is comparatively larger than dry process. In is because the raw material in slurry form is directly fed into the kiln which has ...

Cement concrete is an important construction material. Its importance is increasing every day. It is a composite material consisting of a binding material, which is essentially cement, inert mineral Filler, known as aggregates and water. Thus cement concrete can be prepared by mixing above ingredients in a fixed proportion.

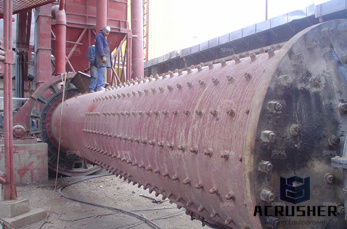

Tube mill, also known as ball mill, is a kind of medium moving crushing equipment, widely used in metal ore and non-metal ore concentrator, metallurgy, building materials, chemical industry and power sector and other basic industries in material crushing.In cement industry, the role of tube mill is not important, dry and wet production must use the corresponding specifications of tube mill to ...

Advantage And Disadvantage Of Cement . Wet Process for Manufacturing of Cement. The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process.

advantages disadvantages of cement manufacturer. The Advantages of Wet Process Use in Cement IndustrySmall Gold Mining advantages disadvantages of wet grinding or wet process of cement manufacturing advantages 【Live Chat】 The Powder Concentrator of industrial waste cement grinding turning waste into treasure is a new environmentally friendly industry .

Advantage And Disadvantage Of Cement Crusher Mills, Cone. advantages and disadvantages of pre grinding process for making cement. advantages and disadvantages of ball mill in size reduction MOBILE CRUSHER Mobile Crusher Advantages And Disadvantages Of Block Machine Production Pastes. get price

WhatsApp)

WhatsApp)