WhatsApp)

WhatsApp)

process of iron milling. Milling steel The machinability of steel differs depending on alloying elements heat treatment and manufacturing process forged cast etc In soft low carbon steels builtup edge and burr formation on the workpiece are the main issues In harder steels the positioning of the cutter becomes more important to avoid edge chipping

The first step of processing corn germ from wet milling or dry milling is to ... The solvent extraction process uses hexane or other solvents to wash the corn oil from the prepared flakes or press cake. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the ...

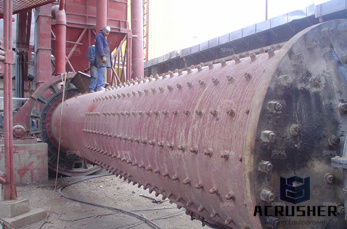

Technologies used up to date for processing low-grade iron ores in Brazil, in particular itabirites, have consisted of three or four stages of crushing followed by ball milling.

The authors examined the laser surface alloying with different powders on different rolls, such as C-B-W-Cr powders on high Ni-Cr infinite chilled cast-iron rolls [81], C-B-W-Cr and NiCr-Cr 3 C 2 powders on NCIR [38], NiCr-Cr 3 C 2 powders on semisteel rolls [39], and NiCr-Cr 3 C 2 powders on cast steel rolls [40].A comparison about the alloyed layer quality (cracks and pores) and the wear ...

Jan 01, 2008· Milling And Boring. CGI does provide approximately 50 percent better milled surface finish (Rz) than gray cast iron, which means that either fewer machining passes may be needed or a separate finishing tool may not be necessary to deliver the requisite finish. During machining, CGI does not produce component edge breakout as the tool exits the cut.

Puddling process, Method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of oxidizing substances (see oxidation-reduction). Invented by Henry Cort in 1784 (superseding the finery process), it was the first method that allowed wrought iron to be produced on a large scale.

A rice milling system can be a simple one or two step process, or a multi stage process. In a one step milling process, husk and bran removal are done in one pass and milled or white rice is produced directly out of paddy.; In a two step process, removing husk and removing bran are done separately, and brown rice is produced as an intermediate product.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semi-finished casting products, such as slabs, blooms, and billets.

Mill Machining, Milling Process, Horizontal & Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

iron grinding mill process (PDF) SIZE REDUCTION BY GRINDING METHODS Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials.

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

The top of the Cu is patterned with a photo-resist mask designed to leave behind an array of Cu dots. When the ion milling begins, secondary Cu ions are detected by the SIMS detector as having a significant intensity. As the milling process starts to punch through the Cu top layer and into the SiO2, the intensity of Cu starts to diminish and the presence of SiO2 is first detected and then ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. Aggregate milling processes are also used to remove or separate . is also used as a synonym for a slitting mill, which makes rods of iron or other metal. Get Price; Ore ...

Mar 15, 2003· The Continuous Casting Process. Wells Manufacturing Co. first introduced the process of continuous casting of gray and ductile iron to the United States in the 1960s. The original machines were used to make high quality gray cast iron that could compete favorably with sand castings. ... Advances in the machining of cast iron are by no means ...

Extraction of iron. Iron atoms are found in the compounds FeO, Fe 2 O 3 and Fe 3 O 4 and in rocks like haematite and magnetite. South Africa is the seventh largest producer of iron ore in the world. Iron has been mined in South Africa for thousands of years. South African archaeological sites in Kwa-Zulu Natal and Limpopo provide evidence for this.

1. Milling. Grains are selected depending on beer style. The grains are milled into the grist hopper [A] to allow us to extract essential ingredients. 2. Mashing. The grains are moved from the mill room through a feed auger [B] to the mash tun [C]. Hot water is added to form the mash. This process converts the grain starch to sugars. 3. Lautering

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached ...

Iron Ore Grinding Mill Iron Ore Milling Process Machine; Iron Ore Crushing Machine Ultrafine Mill,Raymond . Iron ore crushing machine iron is found in the worlds oldest and most widely used, is the largest amount metal, the metal consumption of about 95 of total consumptionon ore is mainly used for iron and steel industry, smelting iron and steel according tothe different carbon contente ...

May 24, 2017· I doubt is your mill table is "plain" cast iron. It's more likely one of the harder alloys in a large family of cast irons the recipes for which fill a thick red book to be found in every metallurgist's personal library. ASM Specialty Handbook: Cast Irons - Google Books I seem to recall "Meehanite" is a proprietary process, not a specific alloy.

process of milling of iron ore sepkids. process of milling of iron ore africar-hire. ASARCO » Milling. The haul trucks carry the ore out of the pit along a haulage road with a slope mineral chalcopyrite which is a naturally occurring compound of copper, iron, About 80 percent of the water used in the milling process is reclaimed and ...

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned.Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and it is the ...

Milling steel. The machinability of steel differs depending on alloying elements, heat treatment and manufacturing process (forged, cast, etc.). In soft, low-carbon steels, built-up edge and burr formation on the workpiece are the main issues. In harder steels, the positioning of the cutter becomes more important for avoiding edge chipping.

Milling is an important process of manufacturing technology and basically it refers to the removal of metal from the work piece using a tool which has several cutting points and is rotating about its axis. Thus each cutting point removes a little bit of the metal but since there are multiple such points and the tool is rotating at a fast speed, the overall removal is quite brisk.

WhatsApp)

WhatsApp)